How to Choose the Right Straight Valves: A Comprehensive Guide with Industry Insights and Best Practices

Selecting the appropriate straight valves is a crucial decision for various industries, ranging from oil and gas to water treatment and manufacturing. According to a recent market analysis by Grand View Research, the global valve market is projected to reach $93.93 billion by 2025, highlighting the growing significance of precise and efficient valve solutions.  Straight valves, in particular, play an essential role in fluid control systems, ensuring optimal flow characteristics and minimal pressure drop, which are vital for maintaining system efficiency and reliability.

Straight valves, in particular, play an essential role in fluid control systems, ensuring optimal flow characteristics and minimal pressure drop, which are vital for maintaining system efficiency and reliability.

Understanding the nuances of straight valve selection can significantly impact operational performance. A study published in the Journal of Engineering and Technology explored the correlation between valve selection and system efficiency, revealing that improper valve choices can lead to losses of up to 30% in energy consumption. This underscores the importance of following best practices when selecting straight valves, as the right choice not only enhances operational efficiency but also contributes to long-term cost savings and sustainability efforts in industrial applications. In this comprehensive guide, we will delve into the factors that influence the selection of straight valves, supported by industry insights and practical approaches to ensure optimal performance and reliability in your systems.

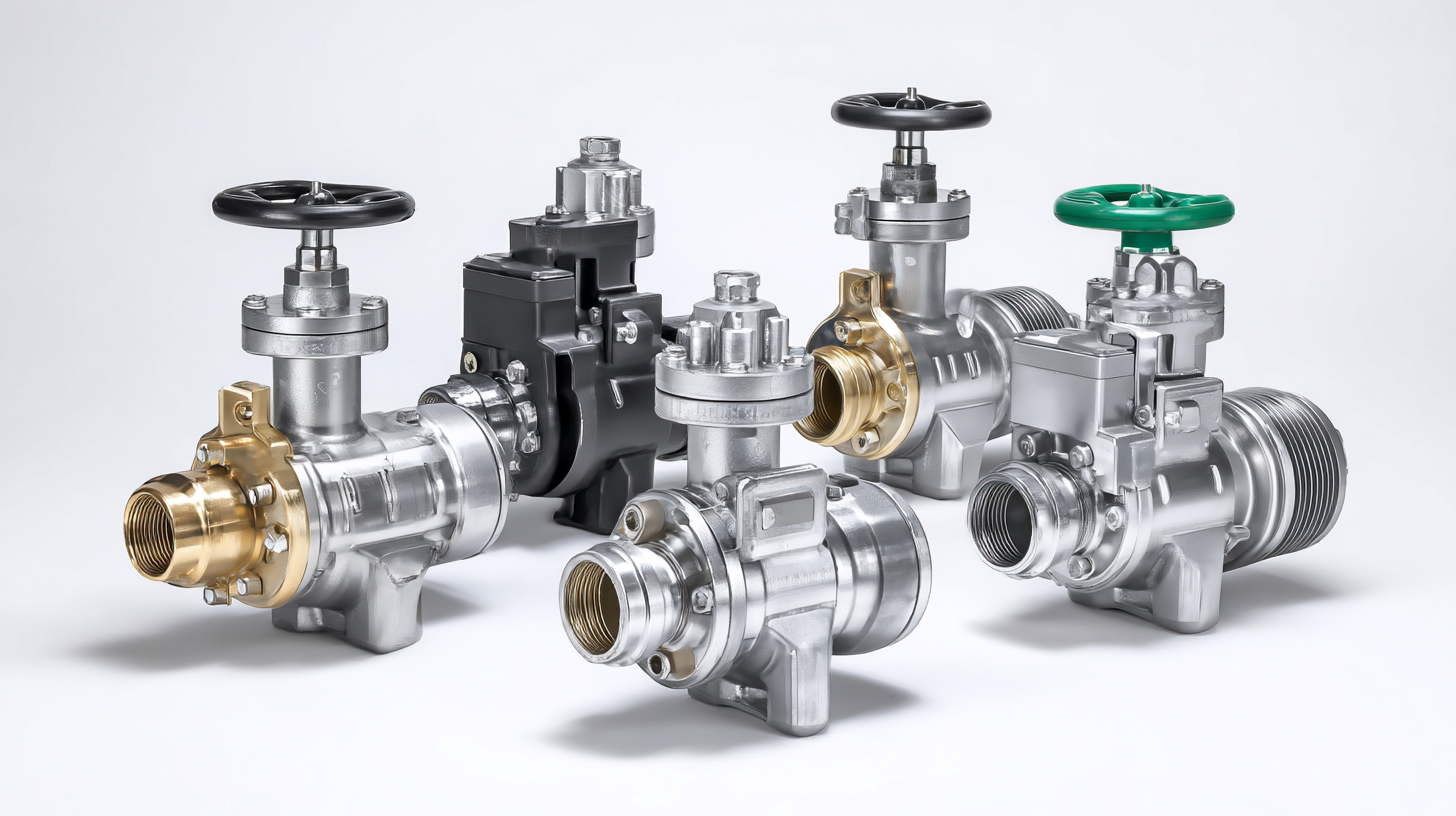

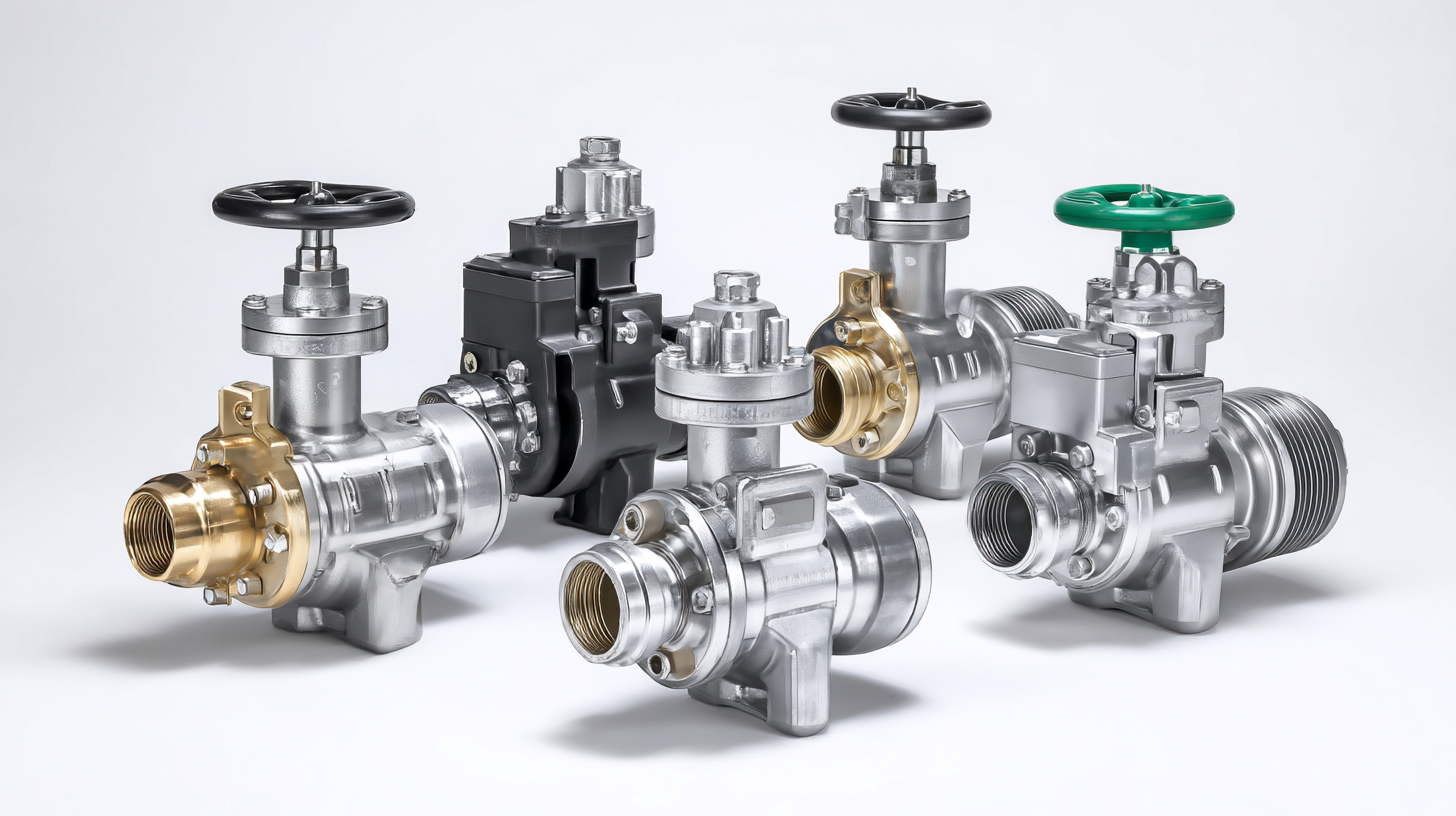

Understanding Straight Valves: Types and Applications in Modern Industries

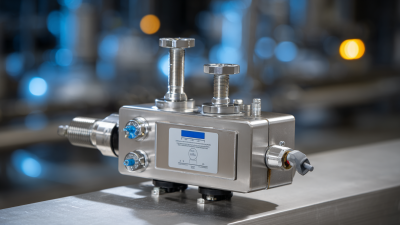

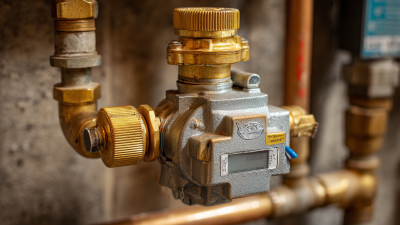

Straight valves play a crucial role in a variety of industrial applications, serving as essential components in systems that require the efficient and reliable control of fluid flow. In modern industries, the choice of straight valves can significantly influence the operational efficiency and maintenance costs. Among the typical types of straight valves, those made from brass, stainless steel, and plastic are prominently used across sectors such as HVACR, plumbing, and industrial processes. The specific application often dictates the type of material and design necessary to ensure optimal performance and durability.

In the North America copper tubes market, straight tubes, for instance, have gained traction due to their excellent thermal conductivity and corrosion resistance, making them ideal for HVACR applications. According to industry data, the demand for type L and type M straight copper tubes is expected to grow in response to the rising need for reliable plumbing solutions and efficient refrigerant lines. Additionally, the versatility of straight valves in applications ranging from industrial machinery to residential plumbing highlights their importance in maintaining seamless operation across various sectors. As industries continue to evolve, understanding the specific types of straight valves available and their respective applications becomes imperative for achieving sustained operational excellence.

Key Factors to Consider When Selecting Straight Valves for Your System

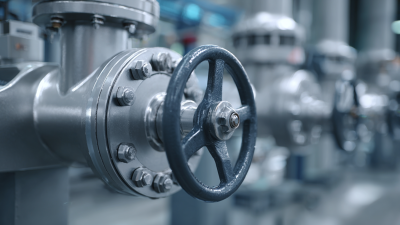

When selecting straight valves for your system, several key factors must be taken into account to ensure optimal performance and reliability. Firstly, it is essential to consider the valve size and type based on the flow rate and pressure requirements of your application. An adequately sized valve will help prevent issues such as flow turbulence or pressure loss, which can compromise system efficiency. Moreover, different types of straight valves, such as ball, gate, or globe valves, offer distinct advantages and limitations in terms of flow control, sealing capability, and response time.

Another critical factor is the material of the valve, which should align with the properties of the fluids being handled. Corrosion resistance, temperature tolerance, and compatibility with the medium are vital considerations to prevent premature failure and ensure the longevity of the valve. Additionally, understanding industry standards and certifications pertinent to your application can help in selecting a reliable product that meets safety and regulatory requirements. By thoroughly evaluating these factors, you can make an informed decision that enhances the efficiency and safety of your system.

Industry Insights: Trends and Innovations in Straight Valve Technology

In recent years, the straight valve technology landscape has witnessed remarkable advancements driven by the need for greater efficiency and sustainability in various industries. Manufacturers are increasingly focusing on innovative designs that enhance the flow characteristics while minimizing pressure drops. These innovations, such as the use of computational fluid dynamics (CFD) in valve design, can lead to improved performance metrics, ensuring that operations run smoothly and effectively.

Moreover, the emergence of smart valve technology is reshaping how straight valves are integrated into control systems. By incorporating IoT sensors and real-time monitoring capabilities, these smart valves provide enhanced data analytics, enabling predictive maintenance and optimal operation. This transition toward automation and remote control not only improves reliability but also contributes to significant energy savings, making straight valves more efficient than ever before.

As industries continue to evolve, staying informed about these trends and innovations is crucial for selecting the right straight valve solutions that meet current and future demands.

Best Practices for Installing and Maintaining Straight Valves for Optimal Performance

When it comes to installing and maintaining straight valves, following industry best practices is crucial for ensuring optimal performance. According to the Fluid Control Institute, improperly installed valves can lead to a 20-30% decrease in efficiency, which translates to significant cost implications for industries reliant on fluid control systems. Thus, proper alignment and secure mounting are essential during installation. Implementing a torque specification derived from manufacturer guidelines is also advised to prevent leakage and ensure the longevity of the valve.

Regular maintenance routines should not be overlooked, as they play a vital role in maintaining efficiency. The National Association of Corrosion Engineers reports that up to 50% of valve failures are due to inadequate maintenance. This includes routine inspections for signs of wear or corrosion, proper cleaning to prevent the buildup of particulates, and timely replacement of sealing materials. Using predictive maintenance strategies, such as monitoring the valve’s pressure and temperature, can help detect potential issues before they escalate, ensuring continuous and reliable operation in industrial settings.

How to Choose the Right Straight Valves: A Comprehensive Guide with Industry Insights and Best Practices

| Valve Type |

Material |

Pressure Rating (PSI) |

Temperature Range (°F) |

Applications |

Maintenance Frequency |

| Gate Valve |

Cast Iron |

150 |

-20 to 200 |

Water Supply, HVAC |

Annual |

| Globe Valve |

Stainless Steel |

300 |

-40 to 400 |

Steam, Oil |

Semi-Annual |

| Ball Valve |

PVC |

200 |

-10 to 140 |

Chemical Processing |

Quarterly |

| Check Valve |

Bronze |

250 |

0 to 300 |

Pumping Stations |

Annual |

| Butterfly Valve |

Aluminum |

150 |

-30 to 150 |

Water and Wastewater |

Bi-Annual |

Evaluating Manufacturers: How to Choose Reliable Suppliers for Straight Valves

When selecting the right suppliers for straight valves, it's crucial to evaluate the manufacturers thoroughly to ensure reliability and quality. According to a recent industry report by MarketsandMarkets, the global valve market is projected to reach $91 billion by 2025, indicating a growing demand for high-quality valves across various sectors. This surge emphasizes the importance of choosing manufacturers with proven track records in delivering durable and efficient products.

One of the key factors to consider is the manufacturer's experience and reputation. A supplier with over 15 years in the industry and a track record of compliance with international standards, such as ISO 9001, is generally more reliable. Additionally, data from the American Valve Manufacturers Association shows that approximately 60% of valve failures can be attributed to subpar manufacturing processes. Engaging with suppliers who employ advanced manufacturing technologies and quality control measures can mitigate this risk, ensuring you receive products that meet industry standards and specialized applications.

Evaluation of Straight Valve Suppliers by Performance Metrics

Straight valves, in particular, play an essential role in fluid control systems, ensuring optimal flow characteristics and minimal pressure drop, which are vital for maintaining system efficiency and reliability.

Straight valves, in particular, play an essential role in fluid control systems, ensuring optimal flow characteristics and minimal pressure drop, which are vital for maintaining system efficiency and reliability.