Top 10 Flow Valves for Enhanced Fluid Control in Industrial Applications

In the dynamic landscape of industrial operations, effective fluid control is paramount for optimizing efficiency and ensuring operational safety. At the heart of this process lies a crucial component: flow valves. These devices regulate the flow of liquids and gases within various systems, making them indispensable in industries ranging from manufacturing to oil and gas. As industrial applications become increasingly complex, the demand for advanced flow valve technologies rises, prompting engineers and operators to seek out the best solutions for their specific needs.

In this article, we will explore the top 10 flow valves that stand out for their innovative designs, reliability, and performance in enhancing fluid control. Each of these flow valves has been selected based on its capabilities to manage fluid dynamics, withstand harsh environmental conditions, and provide precise control. Whether it is for throttling, shutdown, or emergency applications, understanding the strengths and functionalities of these valves can significantly impact the efficiency of industrial processes. Join us as we delve into the world of flow valves, uncovering the standout options that can elevate your operational capabilities.

Top Trends in Flow Valve Technologies for 2025

As we head into 2025, the flow valve industry is experiencing transformative trends that promise to enhance fluid control in industrial applications. Notably, advancements in smart valve technology are gaining traction. According to a recent report by MarketsandMarkets, the smart valve market is projected to grow from $3 billion in 2020 to over $7 billion by 2025, driven by the increasing demand for automation and improved operational efficiency. This trend emphasizes the integration of IoT and AI technologies, enabling real-time monitoring and control that enhances decision-making.

Another significant trend is the shift towards energy-efficient and environmentally friendly valve designs. A study by Frost & Sullivan highlights that manufacturers are focusing on creating valves that not only reduce operational costs but also adhere to stricter environmental regulations. The adoption of new materials and innovative sealing technologies contributes to lower emissions and leaks, thus promoting greener practices in industries such as oil and gas, water management, and chemical processing.

Tips: Consider investing in smart valve technologies to optimize your fluid control processes. This investment not only helps in achieving better efficiency but also aligns your operations with future trends. Additionally, evaluate the environmental impact of your current valve systems and explore newer, eco-friendly options that comply with upcoming regulations. Sustainable choices not only enhance your corporate responsibility but can also lead to cost savings in the long run.

Key Features to Look for in Industrial Flow Valves

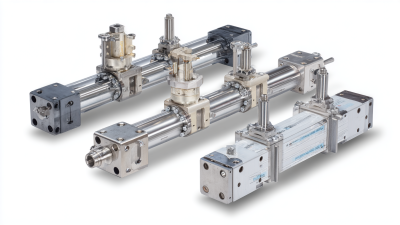

When selecting flow valves for industrial applications, there are several key features to consider that can significantly enhance fluid control. First and foremost, the material of the valve is crucial, as it must be compatible with the specific fluid to prevent corrosion or contamination. Common materials include stainless steel, brass, and various plastics, each offering unique benefits depending on the application’s requirements. Additionally, the valve's size and type—whether it be ball, gate, or globe—should align with the intended flow rate and pressure levels.

Another important feature is the actuation method, which can range from manual to automated systems. Automated valves provide greater precision and responsiveness, particularly in high-demand scenarios where real-time adjustments are necessary. Furthermore, look for valves equipped with advanced sealing technologies to ensure minimal leakage and enhance operational safety. Other valuable attributes may include ease of maintenance, operational temperature range, and pressure rating, all of which play vital roles in ensuring optimal performance and longevity in industrial environments.

Top 10 Flow Valves for Enhanced Fluid Control in Industrial Applications

| Valve Type |

Material |

Max Pressure (psi) |

Temperature Range (°F) |

Key Feature |

| Ball Valve |

Carbon Steel |

6000 |

-20 to 400 |

Quick Shut-off |

| Gate Valve |

Stainless Steel |

1500 |

-50 to 450 |

Full Bore Flow |

| Globe Valve |

Brass |

2000 |

-10 to 350 |

Precise Flow Control |

| Check Valve |

PVC |

150 |

32 to 140 |

Backflow Prevention |

| Butterfly Valve |

Aluminum |

300 |

-20 to 200 |

Compact Design |

| Solenoid Valve |

Stainless Steel |

350 |

-10 to 180 |

Automated Operation |

| Pressure Relief Valve |

Brass |

1500 |

-40 to 250 |

Safety Feature |

| Float Valve |

PVC |

300 |

32 to 140 |

Automatic Level Control |

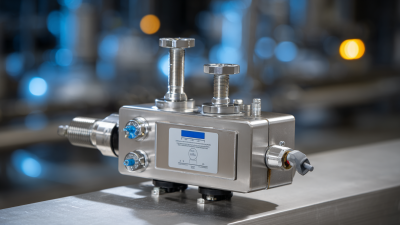

| Diaphragm Valve |

EPDM |

150 |

-10 to 180 |

Leak-proof Design |

| Control Valve |

Stainless Steel |

2000 |

-20 to 400 |

Flow Regulation |

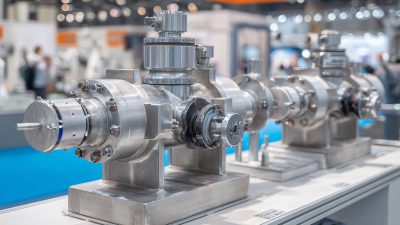

Comparative Analysis of the Best Flow Valve Brands

When it comes to fluid control in industrial applications, selecting the right flow valve is critical for operational efficiency and safety. A comparative analysis of leading flow valve brands reveals distinct advantages in performance, durability, and design. Brands such as Parker, Swagelok, and Camozzi have established strong reputations due to their innovative technologies and consistent quality. These companies offer a variety of flow valve types suited for different applications, from automated systems to manual control.

**Tips:** Always consider the specific requirements of your application, including temperature, pressure, and fluid type, when choosing a flow valve. Conducting thorough research and seeking advice from industry experts can help ensure you select a valve that meets your needs.

While exploring the best valve options, pay attention to the materials used in their construction, as these impact the valve's longevity and resistance to corrosion. Additionally, look for brands that provide robust customer support and comprehensive warranties, as these factors can enhance your overall experience and safeguard your investment.

**Tips:** Regular maintenance and inspection of flow valves are essential to prevent failures and prolong their lifespan. Ensure that you implement a proactive maintenance schedule to catch potential issues before they escalate.

Applications of Advanced Flow Valves in Various Industries

Advanced flow valves play a pivotal role across various industrial applications, ensuring precise fluid control and enhancing operational efficiency. In sectors such as oil and gas, chemical processing, and water treatment, these valves are vital for maintaining optimal flow rates and protecting systems from operational hazards. For instance, pressure relief valves can prevent system overloads, while control valves adjust flow dynamically based on real-time data, ensuring optimal process conditions and safety.

**Tips:** When selecting flow valves, it's crucial to assess the specific requirements of your application, such as fluid viscosity and temperature range. Collaborating with manufacturers who offer customization options can help tailor solutions that meet your unique operational challenges.

In the pharmaceutical industry, advanced flow valves are used to manage sterile processes, maintaining product quality and compliance with stringent regulations. Similarly, in food and beverage production, hygienic flow valves are essential for preventing contamination and facilitating easier cleaning. Leveraging modern valve technology not only improves product integrity but also boosts overall productivity.

**Tips:** Regular maintenance and monitoring of flow valve performance are essential to ensure longevity and reliability. Implementing predictive maintenance strategies can help identify potential failures before they affect production.

Top 10 Flow Valves for Enhanced Fluid Control in Industrial Applications

This chart represents a comparison of different types of flow valves used in various industrial applications based on their effectiveness in fluid control. The data highlights the performance rating of each type, measured on a scale from 0 to 100, where higher values indicate better fluid control capabilities.

Future Innovations in Flow Valve Design and Functionality

The future of flow valve design and functionality is poised for significant innovation, driven by advancements in smart technology and materials science. Recent reports from the Global Flow Control Market indicate that the sector is expected to grow at a CAGR of 6.3% from 2023 to 2030, largely fueled by the increasing demand for automation in industrial applications. Next-generation flow valves are incorporating IoT capabilities, enabling real-time monitoring and predictive maintenance. This transition not only enhances operational efficiency but also minimizes downtime, a critical factor in industries like oil and gas, where even a small increase in reliability can lead to substantial cost savings.

Furthermore, the integration of advanced materials such as composite polymers and lightweight alloys is transforming the durability and performance of flow valves. According to a 2022 study by the International Journal of Fluid Control, these new materials can withstand higher pressures and corrosive environments, thus extending the lifecycle of valves used in harsh settings. As industries realign their sustainability goals, eco-friendly designs are also on the rise, as they reduce energy consumption and emissions. The ongoing research into biomimetic designs, inspired by nature’s efficiencies, signals a promising direction for future flow valve innovations, catering to an ever-evolving industrial landscape.