Understanding Top Process Valves for Industrial Applications?

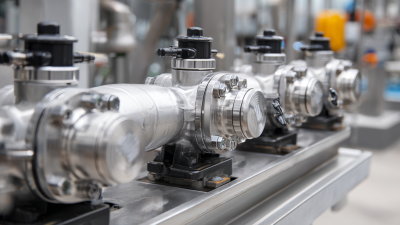

In the realm of industrial applications, understanding process valves is crucial. These components control the flow of liquids and gases, making them essential for efficiency. John Smith, a renowned expert in process engineering, states, “Effective management of process valves can significantly impact production performance.” This perspective highlights the importance of these valves in various industries.

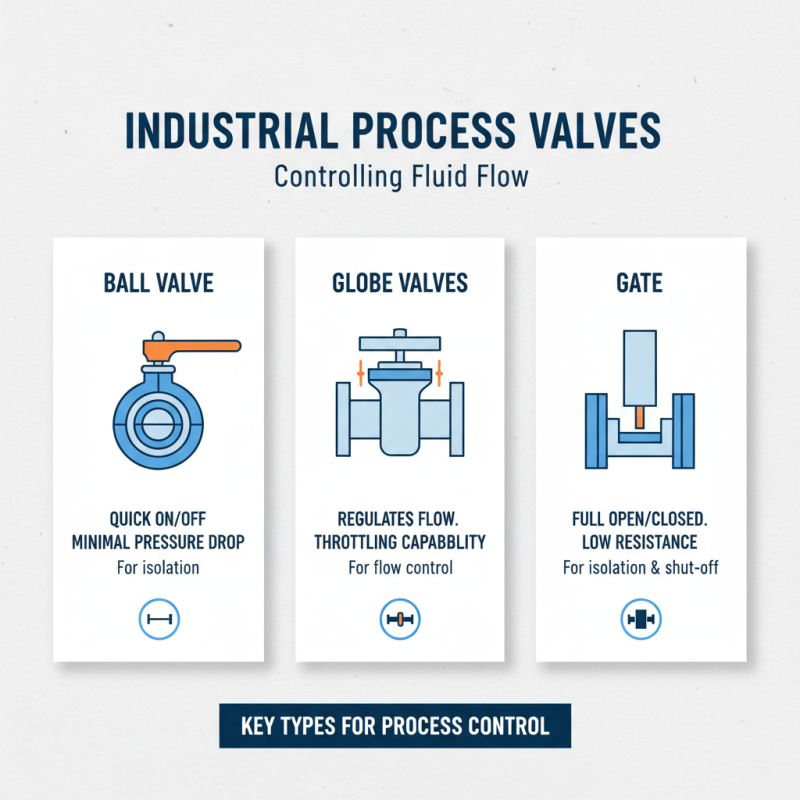

Process valves come in several types, including ball, gate, and globe valves. Each serves a unique purpose. For instance, ball valves offer quick shut-off, while globe valves are ideal for throttling. This variety presents opportunities, but it can also lead to confusion. Selecting the right valve is not always clear-cut. Industries must consider each valve’s specifications carefully.

Maintaining these critical components is equally vital. Neglect can lead to leaks and inefficiencies. Companies often overlook maintenance schedules, risking production downtime. Thus, a proactive approach is required to ensure reliability. Understanding process valves better can transform operational effectiveness, yet many still view them as merely mechanical parts. Recognizing their strategic role is essential for growth.

Overview of Process Valves and Their Importance in Industries

In industrial applications, process valves play a vital role. They control the flow of liquids, gases, and slurries. Choosing the right valve impacts efficiency and safety. Process valves must match the specific requirements of each operation. They ensure proper pressure management and flow rate. This is crucial in preventing system failures.

Tips: Regular maintenance checks can extend valve life. Keep an eye on wear and tear. Even minor leaks can lead to major problems. Valves should be inspected frequently.

Valves come in various types: globe, ball, gate, and check. Each type has its unique purpose. For example, globe valves are ideal for throttling. Ball valves provide an excellent sealing capability. However, not all options fit every situation. Therefore, it is essential to assess your needs before selecting a valve.

Tips: Don't overlook installation quality. Poor installation can lead to efficiency loss. Make sure technicians follow best practices. Sometimes, a different type of valve may be better suited for a specific task. Consider flexibility in your choice.

Understanding Top Process Valves for Industrial Applications

| Valve Type |

Material |

Application |

Temperature Range (°F) |

Pressure Rating (PSI) |

| Ball Valve |

Carbon Steel |

Oil and Gas |

-20 to 300 |

1500 |

| Globe Valve |

Stainless Steel |

Water Treatment |

-40 to 450 |

600 |

| Check Valve |

Brass |

HVAC |

-10 to 250 |

300 |

| Butterfly Valve |

PVC |

Chemical Processing |

-20 to 180 |

150 |

| Solenoid Valve |

Aluminum |

Automotive |

-40 to 200 |

100 |

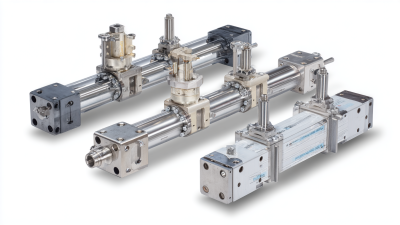

Types of Process Valves Used in Industrial Applications

In industrial applications, understanding process valves is crucial. These valves control fluid flow in various systems. The most common types include ball, globe, and gate valves. Each type serves a distinct purpose in controlling pressure and flow.

Ball valves are widely used due to their high reliability and ability to seal tightly. They excel in on/off applications. Data shows they can operate under high pressures, up to 10,000 psi in some cases. Globe valves, on the other hand, offer excellent flow regulation. They are favored in throttling applications. But, they come with a drawback—they can create pressure drops, which may affect overall system efficiency.

Gate valves are designed for full flow. They are ideal for applications where the medium does not require frequent adjustment. However, their slow operation can impede system responsiveness. Reports indicate that about 20% of valve-related failures stem from improper selection. Inadequate sizing can lead to leaks and inefficiencies. Each valve type has its place, but careful consideration is necessary to mitigate risks.

Key Features and Specifications of Top Process Valves

Process valves play a critical role in various industrial applications. Understanding their key features and specifications is essential for optimizing performance. One of the top features of process valves is their pressure rating. Many valves support a pressure range up to 600 psi, making them suitable for high-pressure applications. Additionally, material choices vary widely, with options from stainless steel to brass, impacting corrosion resistance and durability.

Another crucial specification is the valve size. Common sizes range from 1 inch to over 12 inches in diameter. This flexibility allows for precise control in a variety of processes. Actuation methods are also key. Manual, electric, and pneumatic actuators each offer unique advantages. Reports indicate that automated valves can improve operational efficiency by as much as 30%.

Tips: Regular maintenance of valves is essential. Inspect for leaks or wear regularly. Consider implementing automation for better process control. Evaluate the environment where the valve operates; extreme temperatures can affect performance. Reflections on past failures can often guide future improvements. Investing time in the right specifications for your application can prevent costly downtimes.

Factors Influencing the Selection of Process Valves

Choosing the right process valves for industrial applications involves understanding several key factors.

First, consider the medium being controlled.

Different fluids, gases, and slurries require specific valve materials and designs.

For instance, corrosive substances can damage standard valves.

Tips:

Always test materials in a controlled environment before full-scale use.

Next, think about the pressure and temperature ranges in your system.

Valves must withstand the operational stresses without failure.

High pressures may require stronger, reinforced designs.

In contrast, low-pressure systems might accept simpler solutions.

Tips:

Regularly monitor system conditions to ensure valve compatibility.

Flow capacity is another critical factor.

Each valve has a flow coefficient that determines how much fluid can pass through.

Matching this with system requirements is essential.

However, oversizing valves can lead to inefficiencies, such as turbulence and energy loss.

Remember, proper selection isn't always straightforward.

Sometimes, it requires adjusting expectations and confirming that designs align with real-world conditions.

Pay close attention to installation and maintenance needs,

as these can significantly impact performance.

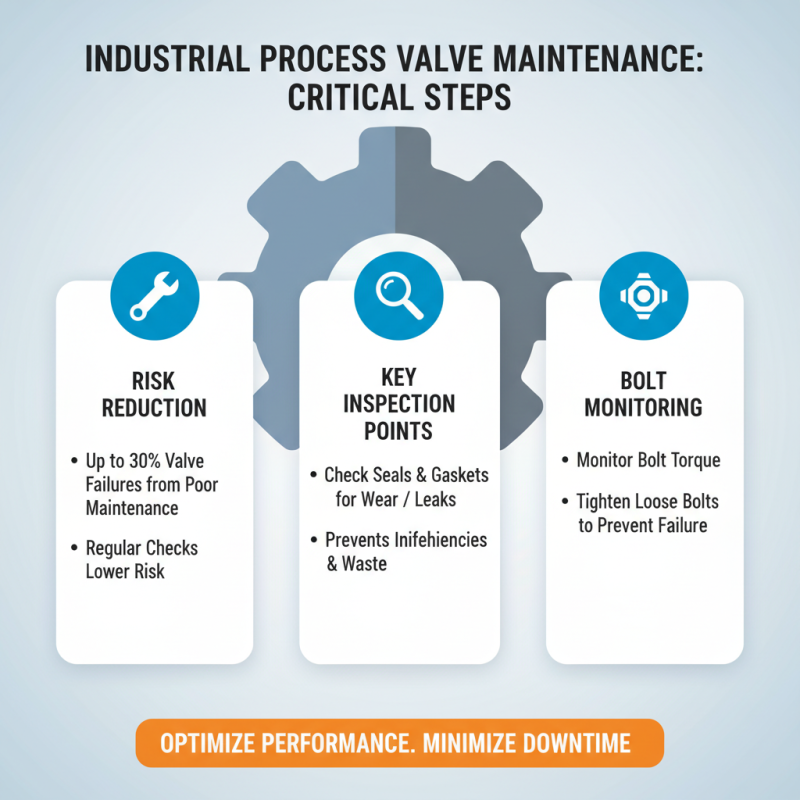

Maintenance and Troubleshooting of Industrial Process Valves

Maintenance of industrial process valves is critical. According to industry data, up to 30% of valve failures occur due to improper maintenance. Regular checks can reduce this risk significantly. Inspecting seals and gaskets for wear is essential. Any leaks can lead to inefficiencies and waste. It is important to monitor torque on bolts as well. Loose bolts can result in valve failure.

Troubleshooting begins with understanding common failure modes. For instance, if a valve often jams, obstruction might be the culprit. A clean workspace is crucial during maintenance. Dirt can easily cause issues. Additionally, actuator responsiveness is key. Testing actuators regularly ensures they function correctly. Some reports indicate that about 40% of valve problems stem from actuator malfunctions.

Aside from regular inspections, documentation plays a major role. Tracking maintenance history can reveal patterns. These patterns provide insight into recurring issues. Often, teams overlook simple fixes until a problem escalates. A proactive approach can save time and resources, highlighting the importance of a structured maintenance plan. Addressing these challenges is vital for ensuring operational efficiency in industrial environments.