Unlocking Efficiency: The Rising Demand for Flow Valves in Industrial Applications in 2023

In recent years, the industrial landscape has undergone significant transformations, and the demand for

flow valves has surged remarkably. According to a recent market report by

MarketsandMarkets, the global flow valve market size is projected to reach

USD 20.3 billion by 2025, growing at a compound annual growth rate

(CAGR) of 3.9% from 2020 to 2025. This rising trend underscores the pivotal role that

flow valves play in optimizing efficiency across various sectors, including oil and gas, water management, and chemical

processing. As industries look to streamline operations and enhance productivity, the integration of advanced flow valves

has proven essential in managing fluid dynamics and minimizing energy waste.

Additionally, a report from ResearchAndMarkets highlights that the increasing

adoption of automation technologies in industrial applications is propelling the demand for high-performance flow valves.

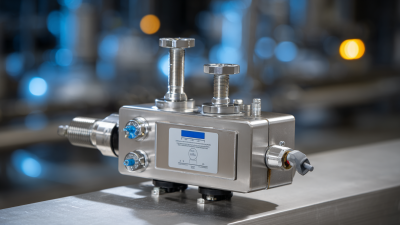

These components are not merely mechanical devices; they are integral to ensuring safety, reliability, and precision in

fluid control systems. With a heightened focus on operational efficiency and sustainability, businesses are increasingly

investing in cutting-edge flow valve solutions to adapt to evolving regulatory requirements and market demands. Therefore,

in 2023, understanding the factors driving this rising demand for flow valves will be crucial for industry stakeholders

seeking to maintain a competitive edge.

Emerging Trends in Flow Valve Technology: Driving Industrial Efficiency in 2023

The rising demand for flow valves in industrial applications is a reflection of several emerging trends in technology and energy efficiency as we move through 2023. As industries increasingly focus on improving operational efficiency, innovative flow valve designs are becoming pivotal. These advanced valves are engineered to optimize fluid control, leading to reduced energy consumption and enhanced productivity. With a projected growth in the control valve market from USD 7.8 billion in 2024 to USD 15.5 billion by 2032, investments in new technologies are expected to drive the industry forward.

**Tips:** When selecting flow valves, look for those that incorporate smart technology for real-time monitoring and control; this can lead to significant savings in both energy and maintenance costs. Additionally, consider partnerships with startups specializing in valve technology to stay updated on the latest innovations and ensure your systems are utilizing the most efficient solutions available.

Further insights into the industrial valves market reveal that it is estimated to grow to USD 121.67 billion by 2024, indicating a robust demand for efficient and high-quality products. As global expansion continues in various sectors, understanding these market dynamics can help businesses strategically position themselves to leverage this growth, ensuring they remain competitive in an evolving landscape.

Unlocking Efficiency: The Rising Demand for Flow Valves in Industrial Applications in 2023

| Application Sector |

Flow Valve Type |

Efficiency Improvement (%) |

Market Growth Rate (%) |

| Oil & Gas |

Control Valves |

15 |

6 |

| Water Treatment |

Ball Valves |

20 |

8 |

| Chemical Processing |

Butterfly Valves |

12 |

5 |

| Pharmaceuticals |

Solenoid Valves |

18 |

7 |

| Food & Beverage |

Check Valves |

10 |

4 |

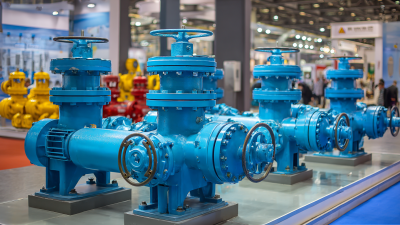

Key Industries Influencing the Demand for Flow Valves in Modern Manufacturing

In 2023, the demand for flow valves is being significantly driven by several key industries that are pivotal in modern manufacturing. The chemical processing sector is one of the largest consumers, accounting for nearly 30% of flow valve applications, as per recent market reports. This industry’s growth is propelled by the increasing need for efficient fluid control systems to enhance production efficiency and ensure safety standards are met. Similarly, the oil and gas industry continues to influence demand, where flow valves play a critical role in the management of fluids under high pressure and extreme conditions.

The power generation sector also stands out, representing approximately 20% of the global flow valve market. As the shift towards renewable energy sources gains momentum, the need for specialized flow control solutions becomes essential, particularly in wind and hydroelectric power systems. This aligns with the findings from the Industrial Valve Market Report, which predicts a compound annual growth rate (CAGR) of 6.2% from 2023 to 2028 in this area.

Tips: When selecting flow valves for your applications, it’s crucial to assess the specific pressures and temperatures your system will encounter. Additionally, consider the materials used for the valve to ensure compatibility with the fluids being managed, as this can significantly affect performance and lifespan. Regular maintenance checks are also essential for keeping flow valves operating efficiently and extending their service life.

The Impact of Automation on Flow Valve Usage and Market Growth

In 2023, the industrial sector is witnessing a significant shift towards automation, driving the demand for flow valves to new heights. According to a report by MarketsandMarkets, the global flow valve market is projected to reach USD 30.75 billion by 2025, growing at a CAGR of 6.8% from 2020. This growth is largely attributed to the increasing need for precise and efficient fluid control in automated systems, where flow valves play a critical role in maintaining optimal performance in various applications such as oil and gas, chemical processing, and water treatment.

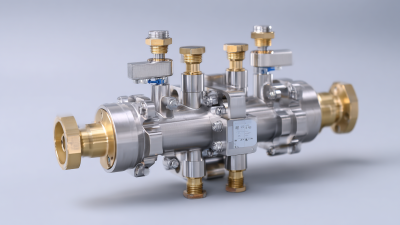

As industries embrace automation technologies like IoT and AI, flow valves are becoming smarter, equipped with advanced features that enhance operational efficiency. The integration of electronic actuators and communication protocols enables real-time monitoring and feedback, allowing for quicker adjustments to flow rates and pressure levels. This not only improves productivity but also reduces downtime, making automated systems more reliable.

Tips for Industry Professionals:

1. Consider investing in smart flow valves that offer connectivity features for better integration with automation systems.

2. Regularly assess your flow management strategy to identify areas where automation can enhance efficiency, ensuring your operations remain competitive.

3. Stay updated with market trends and technological advancements to make informed decisions about future investments in flow management solutions.

Sustainability Considerations: Eco-Friendly Flow Valve Innovations in 2023

The industrial landscape in 2023 is witnessing a significant shift towards eco-friendly technologies, with flow valves at the forefront of this change. According to a recent report by MarketsandMarkets, the global flow control market is expected to grow from $20.71 billion in 2022 to $27.10 billion by 2027, largely driven by the increasing demand for sustainable practices. Flow valves, integral to fluid control systems, are now being designed with materials and technologies that reduce their environmental impact, aligning with the growing emphasis on sustainability in manufacturing.

Innovations in flow valve technology are contributing to greater energy efficiency and reduced resource consumption. For instance, advancements in smart flow valves that incorporate IoT capabilities enable real-time monitoring and optimization of fluid flow, which can result in energy savings of up to 30%, as noted in a report by Research and Markets. Moreover, manufacturers are increasingly turning to recyclable materials for valve construction, further minimizing waste and supporting circular economy initiatives. As industries strive to meet stringent environmental regulations, the adoption of eco-friendly flow valves is not just a trend but a vital step towards achieving sustainability goals.

Unlocking Efficiency: The Rising Demand for Flow Valves in Industrial Applications in 2023

Challenges in the Flow Valve Market: Supply Chain and Regulatory Issues

The flow valve market is currently facing significant challenges that hinder its growth potential, primarily due to supply chain disruptions and evolving regulatory issues. According to a report by Research and Markets, the global flow valve market was valued at approximately $16 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. However, this growth is being threatened by increased raw material costs and logistical challenges stemming from the ongoing impacts of the COVID-19 pandemic.

In addition to supply chain constraints, manufacturers are grappling with stringent regulations that aim to enhance efficiency and safety in industrial applications. The American Society of Mechanical Engineers (ASME) and the Environmental Protection Agency (EPA) have implemented new standards that require advanced designs and materials, driving up compliance costs for companies. In 2023, nearly 40% of industry professionals reported that regulatory compliance has delayed project timelines, according to a survey by the International Society of Automation. These factors combined illustrate the need for strategic planning and innovation in the flow valve sector to navigate the current landscape effectively.