What is a Water Diaphragm Valve and How Does It Work in Fluid Systems

The water diaphragm valve is a critical component in fluid systems, particularly in applications involving the precise control of water flow. According to a recent report by Research and Markets, the global market for diaphragm valves is expected to reach USD 5.6 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth reflects the increasing demand for efficient and reliable flow control solutions in various industries, including water treatment, agriculture, and pharmaceuticals.

At the core of its operation, the water diaphragm valve utilizes a flexible diaphragm that responds to pressure changes, enabling it to open or close and regulate the flow of water. This functionality is crucial, especially in environments where contamination is a concern, as the diaphragm creates a barrier between the fluid and the external environment. In fact, according to the International Water Association, nearly 40% of water produced worldwide is lost due to leaks in aging infrastructure. The implementation of advanced valve technologies, such as the water diaphragm valve, can significantly reduce these losses and improve overall system efficiency.

In conclusion, understanding how a water diaphragm valve works and its application in fluid systems is essential for enhancing operational efficiency and ensuring sustainable water management practices. As industries continue to seek innovative solutions to tackle water scarcity and quality issues, the role of such valves will become increasingly prominent in driving improvements in fluid control systems.

What is a Water Diaphragm Valve?

A water diaphragm valve is a type of valve used to control the flow of fluids through a system. It operates using a flexible diaphragm that acts as a barrier between the fluid and the valve mechanism. When the valve is closed, the diaphragm sits against the valve seat, preventing flow. Conversely, when it is opened, the diaphragm is lifted, allowing the fluid to pass through. This design offers precise control over flow rates and pressure within the system, making it ideal for various applications in water treatment, irrigation, and HVAC systems.

The functionality of the water diaphragm valve is primarily driven by the pressure differential across the diaphragm. When the pressure on one side exceeds that on the other, the diaphragm moves accordingly, either opening or closing the valve. This mechanism allows for quick adjustments and reliable operation, often without the need for complex external control systems. Additionally, diaphragm valves are known for their durability, as they minimize wear and tear from direct contact with the fluid, thus enhancing their longevity in demanding environments.

Key Components of a Water Diaphragm Valve

A water diaphragm valve is an essential component in various fluid systems, particularly in applications requiring precise flow regulation and control. The key components of this valve include the diaphragm, body, actuator, and inlet/outlet ports. The diaphragm is typically made from flexible materials such as silicone or rubber, which allows it to expand and contract, thus opening or closing the flow passage as needed. According to industry reports, diaphragm valves can provide tight shut-off capabilities, achieving leakage rates as low as 0.01% of flow, making them ideal for sensitive applications in water treatment and chemical processing.

The body of the valve is constructed from durable materials such as PVC, stainless steel, or other corrosion-resistant alloys, ensuring longevity and reliability in harsh environments. The actuator can be manual or automated, allowing for easy integration into control systems. In a recent market analysis, over 60% of fluid control professionals reported that automated diaphragm valves significantly improved operational efficiency by providing better control over fluid dynamics.

Furthermore, the guided motion of the diaphragm within the body minimizes wear and tear, extending the operational life of the valve and reducing maintenance costs. This efficient design highlights the importance of diaphragm valves in enhancing system performance in various industrial applications.

How Does a Water Diaphragm Valve Operate?

A water diaphragm valve operates using a flexible membrane, or diaphragm, which is positioned between the fluid flow and the surrounding environment. When the valve is activated, the diaphragm moves in response to pressure changes, effectively opening or closing the flow path. This mechanism allows for precise control of fluid flow, making it particularly useful in various applications, including irrigation systems, water distribution, and industrial processes.

The operation of the valve is essentially simple yet effective. When pressure is applied to one side of the diaphragm, it distorts and either allows or restricts fluid passage. In many designs, the valve can be manually adjusted or controlled automatically through electronic means. This variability in operation not only helps in managing water flow efficiently but also minimizes the risk of leakage due to the diaphragm's ability to create a tight seal when in the closed position. The diaphragm's material and construction also play a critical role in ensuring reliability and longevity through repeated cycles of opening and closing.

What is a Water Diaphragm Valve and How Does It Work in Fluid Systems - How Does a Water Diaphragm Valve Operate?

| Feature |

Description |

| Type |

Diaphragm Valve |

| Material |

Rubber, PTFE, or EPDM |

| Operation |

Uses a flexible diaphragm to control flow |

| Applications |

Water supply, wastewater treatment, chemical processing |

| Pressure Range |

Typically up to 150 psi |

| Advantages |

Leak-proof, minimal maintenance, easy to operate |

| Disadvantages |

Limited high-pressure applications, possible diaphragm wear over time |

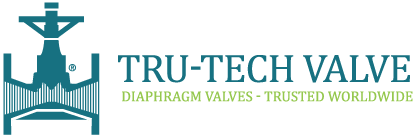

Applications of Water Diaphragm Valves in Fluid Systems

Water diaphragm valves are widely used in various fluid systems due to their ability to provide precise control over fluid flow. These valves are particularly effective in applications where back pressure and leakage are concerns. Their design features a flexible diaphragm that opens and closes in response to changes in pressure, allowing for smooth regulation of flow. This functionality makes them ideal for use in residential water supply systems, irrigation, and chemical processing where secure and reliable flow control is essential.

One prominent application of water diaphragm valves is in agricultural irrigation systems. These valves play a crucial role in managing water distribution, ensuring that crops receive the right amount of water without wastage. Additionally, they are utilized in wastewater treatment facilities, where they help control the flow of sewage and treated effluent, contributing to environmentally safe water management practices. Their robustness and ability to operate under varying pressure conditions make them a preferred choice in industries that demand reliable and efficient fluid control solutions.

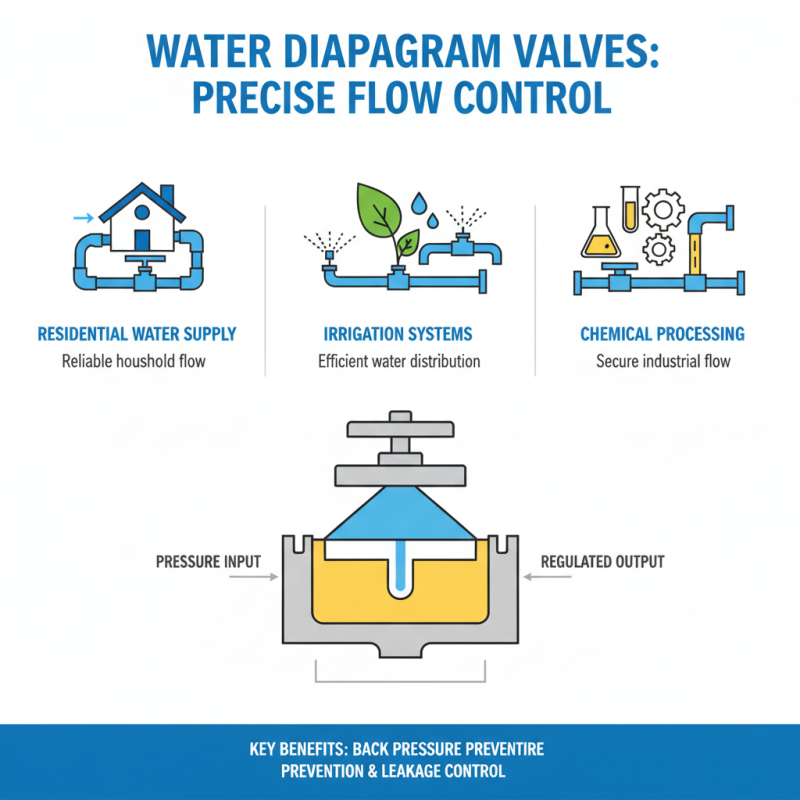

Advantages of Using Water Diaphragm Valves

Water diaphragm valves offer several notable advantages in fluid systems, making them an essential component in various applications. One of the primary benefits is their ability to provide excellent sealing capabilities. The diaphragm, usually made from durable elastomers or thermoplastics, allows for a tight seal that minimizes the risk of leakage. This characteristic is particularly beneficial in systems where maintaining pressure and preventing contamination are crucial.

Another significant advantage of water diaphragm valves is their ease of operation and maintenance. The design typically allows for straightforward installation and adjustment, which can save time and reduce labor costs. Additionally, since the diaphragm isolates the flow from the actuating mechanism, these valves are less susceptible to wear and require less frequent maintenance compared to traditional valves. This increases their reliability and longevity in fluid management systems.

Furthermore, water diaphragm valves can handle a wide range of fluid types and conditions, including corrosive substances. Their versatility makes them suitable for use in industries such as water treatment, agriculture, and chemical processing. By efficiently controlling flow and pressure, diaphragm valves contribute to enhanced system performance and operational efficiency.