Why Choose Chemical Valves for Your Industrial Applications Decoding Their Benefits

In the dynamic landscape of industrial applications, the selection of appropriate valves is crucial for ensuring operational efficiency and safety. Chemical valves, specifically designed to handle the unique challenges of transporting corrosive substances, are gaining prominence in various sectors including chemical processing, pharmaceuticals, and water treatment. According to a report by the Global Valves Market, the demand for chemical valves is projected to grow at a CAGR of 5.6% over the next five years, underscoring their importance in maintaining the integrity of industrial systems.

These valves are engineered with materials that resist corrosion and wear, allowing for reliable performance even in the most demanding environments. In fact, a study by Research and Markets reveals that the chemical industry is the largest end-user of valves, contributing to approximately 35% of the total market share. This highlights the significance of chemical valves in supporting the industry's infrastructure and ensures compliance with stringent safety standards. By opting for specialized chemical valves, businesses not only enhance their operational capabilities but also safeguard their processes from potential hazards associated with fluid dynamics and material compatibility.

Understanding Chemical Valves and Their Functionality

Chemical valves play a crucial role in various industrial applications, primarily due to their ability to handle aggressive and corrosive substances effectively. These valves are specifically designed to withstand harsh environments, ensuring safe and efficient fluid control in processes involving chemicals. According to a report from the Global Market Insights, the chemical valve market is projected to reach $9 billion by 2027, emphasizing the increasing demand for reliable and durable fluid control solutions in the chemical industry.

Understanding the functionality of chemical valves is essential for optimizing industrial processes. These valves are equipped with features that allow for precise regulation of flow and pressure, significantly reducing the risk of leaks and failures. Advanced materials such as high-grade plastics and specialized alloys are often used to fabricate these valves, enhancing their resistance to corrosion and wear. A study published in the Journal of Hazardous Materials highlights that the use of appropriate valve technologies can reduce maintenance costs by up to 30%, which is critical for industries aiming to minimize operational downtime and ensure continuous production.

Moreover, the importance of chemical valves is underscored in the context of safety management. The American Society of Mechanical Engineers (ASME) states that effective valve operation is vital for preventing hazardous releases of chemicals, which can pose significant risks to both personnel and the environment. By implementing state-of-the-art chemical valves, industries can achieve greater control over their operations while adhering to stringent safety regulations, thereby contributing to a more sustainable future.

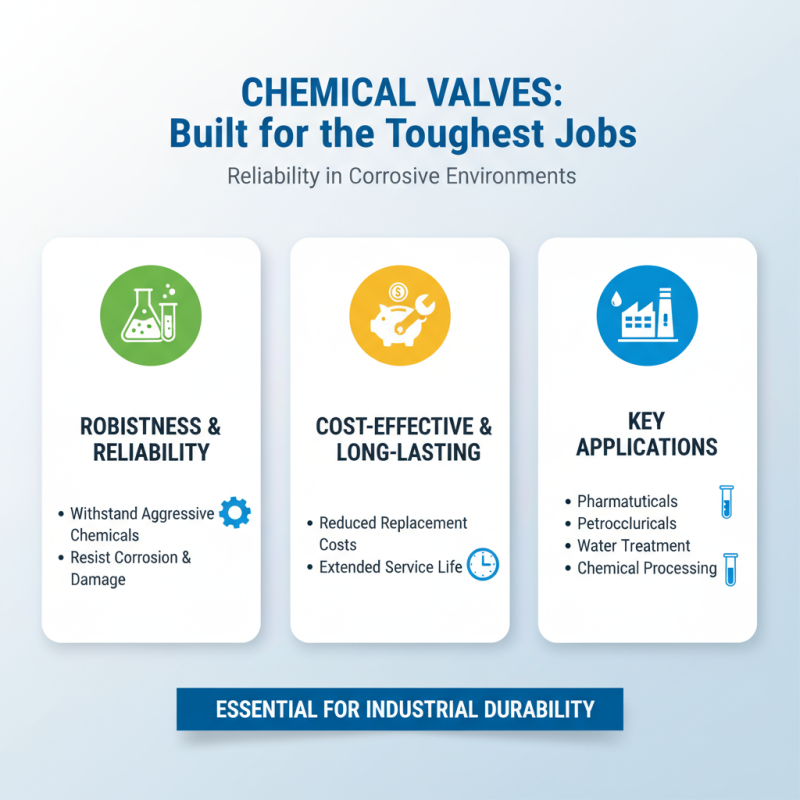

Key Benefits of Using Chemical Valves in Industrial Settings

Chemical valves are essential components in various industrial applications, predominantly due to their robustness and reliability in handling corrosive substances. One of the key benefits of using chemical valves is their ability to withstand aggressive chemicals that can easily damage standard valves. This ensures longevity and reduces replacement costs, making them a cost-effective choice for industries such as pharmaceuticals, petrochemicals, and water treatment.

Additionally, chemical valves often come with enhanced safety features designed to prevent leaks and spills, which can be catastrophic in any industrial setting. These valves are engineered to maintain tight seals and are equipped with fail-safe mechanisms, providing peace of mind for operators and increased protection for the environment. The dual impact of safety and durability makes them indispensable in operations where precision is paramount.

Tips: When selecting chemical valves for your processes, consider the specific type of chemicals you will be handling, as compatibility is crucial. Also, regular maintenance and inspections can extend the life of your valves and prevent unexpected downtimes. Always consult experts or refer to detailed specifications to ensure you make an informed choice.

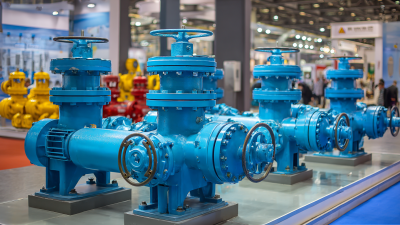

Comparative Analysis: Chemical Valves vs. Traditional Valves

In industrial applications, the choice between chemical valves and traditional valves significantly impacts operational efficiency and safety.

Chemical valves are specifically designed to handle aggressive fluids and harsh environments, often outperforming conventional options in terms of durability and reliability.

Research indicates that chemical valves can resist corrosion and wear better, leading to extended service life.

According to a report by MarketsandMarkets, the chemical valve market is expected to grow at a CAGR of 4.8% from 2021 to 2026, illustrating a growing recognition of their vital role in industrial processes.

When comparing chemical valves to traditional valves, one must consider factors such as material compatibility and maintenance costs.

Traditional valves often require frequent maintenance and replacement due to degradation caused by corrosive materials.

A study by the American Society of Mechanical Engineers suggests that the total lifecycle costs of chemical valves can be significantly lower, as they typically require less frequent servicing, saving both time and operational expenses.

Additionally, they're engineered to minimize leakage, which is critical in environments where hazardous materials are handled, enhancing workplace safety and compliance with environmental regulations.

Furthermore, the adoption of advanced materials in chemical valves, such as PTFE and PFA, enhances their ability to withstand extreme temperatures and pressures.

Industry reports project that such advancements will contribute to a more robust and efficient chemical processing sector, as they cater to the increasing complexity of modern manufacturing operations.

This comparative analysis underscores the necessity of selecting chemical valves over traditional options for industries that prioritize performance, safety, and economic efficiency.

Factors to Consider When Selecting Chemical Valves

When selecting chemical valves for industrial applications, several crucial factors should be taken into account to ensure optimal performance and safety. One significant factor is the material compatibility of the valve with the chemicals it will handle. According to a report by the Chemical Industry Association, choosing the wrong material can lead to corrosion and valve failure, resulting in costly downtime and safety hazards. For instance, valves made from stainless steel or high-performance polymers are often recommended for aggressive chemicals, as they provide better resistance and durability under harsh conditions.

Another important consideration is the valve design, which must align with the specific requirements of your application. Factors such as pressure ratings, flow requirements, and operating temperatures play a vital role in this decision-making process. A study conducted by the Valve Manufacturers Association notes that improper valve selection can lead to inefficient processes, emphasizing the need for thorough performance evaluation. Understanding the flow characteristics and installation conditions will help you choose the optimal valve type, whether it's a ball valve, butterfly valve, or diaphragm valve.

Tips: Always consult with an experienced engineer when making your selection. They can provide valuable insights into the latest industry trends and technologies. Additionally, investing in high-quality valves can lead to long-term savings by reducing maintenance costs and enhancing operational efficiency. It's also beneficial to conduct regular assessments of your existing valve systems to identify any potential risks or inefficiencies.

Benefits of Chemical Valves in Industrial Applications

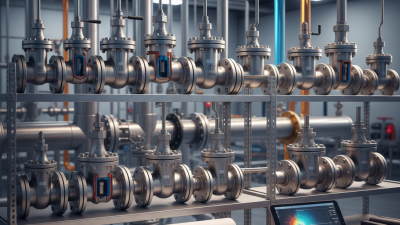

Maintenance and Longevity of Chemical Valves in Industry

Chemical valves play a crucial role in various industrial applications, particularly in processes that involve corrosive substances. Maintaining these valves is essential for ensuring longevity and reliable performance. Regular inspection and preventative maintenance can help identify potential issues before they escalate, reducing the risk of unexpected failures that could disrupt operations.

Chemical valves are often exposed to harsh conditions, so implementing a routine maintenance schedule can significantly extend their lifespan.

Tips for maintaining chemical valves include using appropriate lubricants to reduce friction and wear, regularly checking for leaks and signs of corrosion, and ensuring that valve seals are in good condition. Additionally, operators should be trained to handle these valves correctly to minimize wear and prevent accidental damage.

Employing predictive maintenance techniques, such as vibration analysis and temperature monitoring, can also help in forecasting potential problems, allowing for timely interventions.

Investing time and resources into the proper maintenance of chemical valves not only enhances their operational efficiency but also minimizes downtime and repair costs in the long run. By prioritizing maintenance, industries can significantly improve the overall reliability and longevity of their chemical valve systems.